Processes

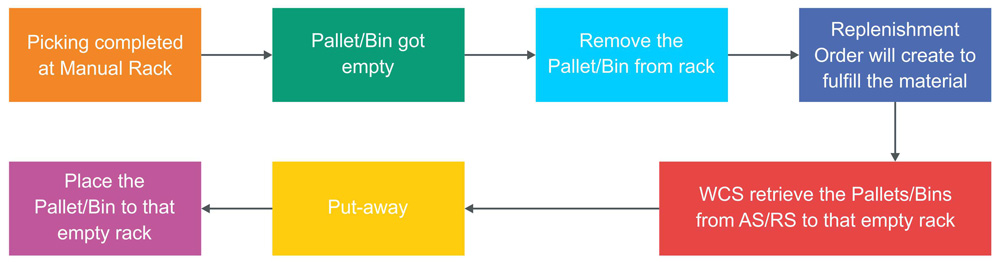

Replenishment

Move materials from reserve storage to the primary storage area to maintain the critical stock levels so that the materials will be picked, packed, and shipped with a minimum waiting time.

WMS continuously monitors the inventory of various SKUs in different storage areas and replenishes them to maintain the minimum stock level required for the picking process.

- Feature to generate replenishment orders automatically

- FIFO and optimized FIFO can be followed to generate replenishment orders

- Priority can be set for picking while generating replenishment orders

- The optimal method can be used for load distribution

- Waiting time is reduced for transporting the bins/pallets to picking orders